+8613480763867

introductionPearl powder, with its unique optical effect and rich color expression, has become one of the indispensable additives in the plastic processing industry. From the shells of household appliances to car interiors, from children's toys to high-end cosmetics packaging, the application of pearl powder is ubiquitous, endowing plastic products with more aesthetic value and commercial appeal. This article will delve into the application of pearl powder in the plastic industry, covering the classification of plastics, the current status and trends of pearl powder usage, as well as usage formulas and techniques. Finally, specific cases will be used to demonstrate the widespread application of pearl plastic.Classification of plastics and current application status of pearl powder1. Polyolefin plastics (such as PE, PP) Due to their excellent physical properties and processability, polyolefin plastics are widely used in daily necessities, packaging materials, etc. Adding pearl powder to these plastics can significantly enhance the appearance grade of products, commonly found in tableware, detergent bottles, etc. The addition of pearl powder enhances the decorative properties of plastic, giving it a metallic or pearl luster and increasing the attractiveness of the product.2. Engineering plastics (such as ABS, PC) are commonly used in the manufacturing of electronic appliances and automotive components due to their excellent mechanical strength and heat resistance. The application of pearl powder in these plastics is not limited to aesthetics, but also involves functionality, such as improving weather resistance and scratch resistance. In automotive interior parts, the use of pearl powder can create a sense of luxury and futurism, meeting consumers' pursuit of quality.3. Thermoplastic elastomers (TPE, TPU) are widely used in shoe materials, toys, sports equipment, etc. due to their soft touch and elasticity. The application of pearl powder in these materials not only enhances the visual effect, but also increases the fun and recognition of the product through special color matching. For example, children's toys with pearl effect are both safe and attractive.Fashion TrendsEnvironmental Protection and Sustainability: With the global emphasis on environmental protection, the combination of biodegradable plastics and pearl powder has become a trend, using renewable resource based pearl powder to reduce environmental pollution.Personalization and Customization: The increasing demand for personalized products from consumers has led to a more diverse range of colors and effects for pearl powder, such as color changing pearl, rainbow pearl, etc., to meet the customization needs of specific brands or products.Technology integration: Combining digital printing, laser engraving and other technologies, the application of pearl powder in plastics is more flexible, achieving the presentation of complex patterns and three-dimensional effects.Using formulas and techniquesChoose the appropriate type of pearl powder: Select pearl powder with high temperature resistance and weather resistance based on the properties of the plastic substrate and the application environment of the final product.Dispersion uniformity: Use efficient mixing equipment and appropriate dispersants to ensure that the pearl powder is evenly distributed in the plastic substrate, avoiding agglomeration and affecting the appearance effect.Control the addition ratio: The amount of pearl powder added is usually between 1% and 5%. If it is too high, it will affect the physical properties of the plastic, while if it is too low, it will not achieve the expected decorative effect. In practical applications, the optimal ratio needs to be determined based on experiments.Application CasesHigh end cosmetics packaging: Silver white pearl powder is added to transparent or semi transparent PC material to create crystal clear bottle caps and containers, reflecting the high-end and exquisite nature of cosmetics.Automotive interior: Adding gold or champagne colored pearl powder to ABS plastic for instrument panel and door panel decoration, creating a luxurious cabin atmosphere and enhancing the driver's riding experience.Outdoor sports equipment: Incorporating UV resistant pearl powder into TPU material outdoor backpacks and sports shoes not only looks beautiful, but also effectively extends the product's service life.epilogueThe application of pearl powder in the plastic industry not only enriches the aesthetic expression of plastic products, but also broadens the functional application boundaries of plastic materials. With the continuous advancement of technology and the diversification of market demand, the innovative application of pearl powder will continue to drive the plastic industry towards higher quality, environmental friendliness, and personalization. By delving into the classification of plastics and mastering the usage techniques of pearl powder, manufacturers can better grasp market trends and create more competitive products.

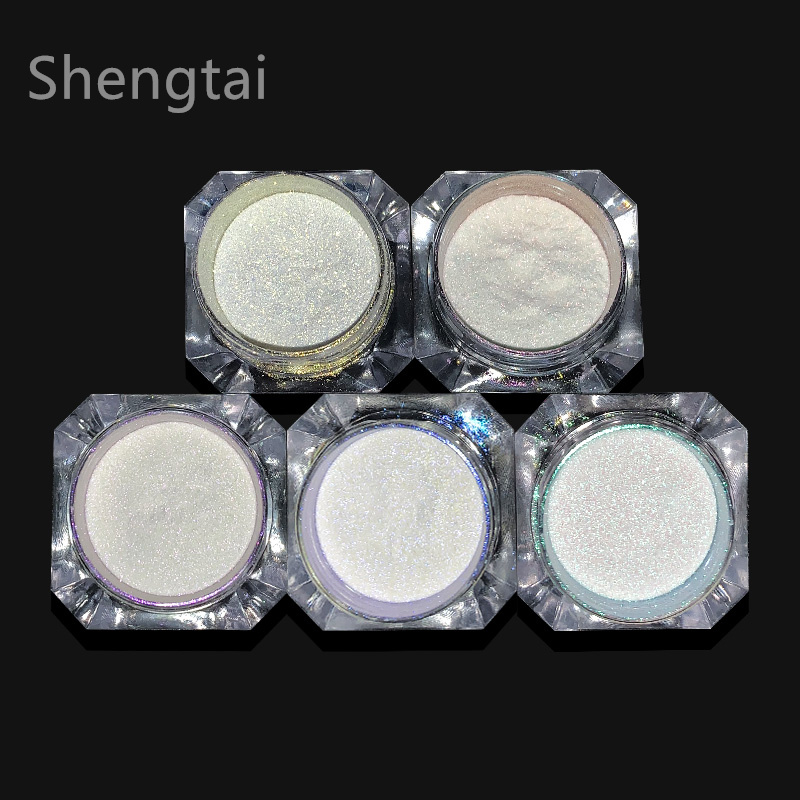

Huizhou Shengtai Pigment Technology Co., Ltd

,